A tire pressure monitoring system (TPMS) uses electronics to monitor the air pressure inside automotive tires. The system transmits real-time tire pressure information to the driver of the vehicle using a simple low pressure warning light in the instrument cluster.

Luxury becomes necessity

The first passenger vehicle to adopt TPMS was the Porsche 959 in 1986. Due to the increased use of Run Flat Tires, TPMS quickly became optional equipment for many luxury passenger vehicles, such as the Audi A8, Mercedes Benz S Class, BMW 7 Series, and the Chevrolet Corvette.

In the fall of 2000, following several fatal accidents involving underinflated tire failure and vehicle rollover, Congress signed into law the Transportation Recall, Enhancement, Accountability and Documentation Act (TREAD). This law mandates the use of a suitable TPMS technology to alert drivers of a severe underinflation condition of their tires. The law requires that all new vehicles produced for the US market after September 2007 have TPMS.

Direct and indirect TPMS

There are two types of tire pressure monitoring systems on the market today – direct and indirect.

Direct TPMS

Direct TPMS systems employ pressure sensors inside each tire to transmit air pressure information from inside the tire to a receiver and then to illuminate a light on the vehicle’s instrument cluster. The system can identify simultaneous underinflation in all four tires in any combination with a typical trigger point of 25% below the recommended cold psi rating.

Direct TPMS systems employ pressure sensors within each tire to transmit air pressure information from inside the tire to a receiver. (Courtesy of Toyota.)

High-line and low-line direct tire pressure monitors

Two types of direct tire pressure monitors are currently in use: high line and low line. High-line systems use low frequency transmitters near each wheel to force wheel-mounted sensors to transmit air pressure information when the ignition is switched on and then periodically as the vehicle is in motion. The transmitters are activated one at a time in sequence so that the system can determine the location of the wheel with low pressure. Some vehicles use only three transmitters to save money. High-line direct tire pressure systems tend to be used on higher-end models.

Low-line system sensors transmit their own signals. Since two or more sensors on a vehicle may transmit simultaneously, individual systems use different methods to ensure signals are received by the vehicle. On some systems the message is re-transmitted in a random or pseudo random pattern multiple times to reduce the effect of interference on communication. Another method is to simply transmit signals more frequently. When sensors detect a rapid change in pressure or a temperature that is too high, they start to transmit immediately. Low-line systems are used on the majority of vehicles due to their lower cost.

How indirect systems work

Indirect systems do not use physical pressure sensors but rather measure the apparent air pressure, by monitoring individual wheel rotational speeds, and other signals available outside the tire itself. An underinflated tire has a slightly smaller diameter than a correctly inflated tire and therefore has to rotate at a higher velocity to cover the same distance as a correctly inflated tire. The system functions in combination with wheel speed sensors for anti-lock braking systems (ABS), and electronic stability control systems (ESC).

Indirect systems do not use physical pressure sensors but rather measure the apparent air pressure, by monitoring individual wheel rotational speeds (Courtesy of Toyota.)

One disadvantage of indirect TPMS is that the driver must calibrate the system by pushing a reset button on the dashboard or through the onboard computer, and if this is performed when any tire is in an underinflated condition, the system will not report correctly.

TPMS Evolution

Electronic systems manufacturer Johnson Controls’ TPMS uses an adaptive auto-learn capability to automatically detect the sensors and determine their positions. The system automatically calculates the positions of each tire sensor, analyzing signal input from the antilock brake system and electronic stability control units at the start of a journey. There is no need for a manual learning procedure, even after a tire change.

Techs can calibrate new sets of tires within two to three minutes. The system can also permanently save additional sensor IDs, increasing the calibration speed of a set of winter tires. After the system detects the saved IDs, the sensors calibrate quicker, even if these tires are mounted in different positions than before.

The system reports low pressure just as precisely for one individual tire as for all four tires. The sensor technology can even detect a minimal 1 psi change in pressure. While the system is direct-measuring, it is unlike comparable systems in that it only uses a single antenna which is integrated directly into the TPMS control unit. Because the receiver software calculates all of the information needed to analyze the signals, it requires no other components apart from the tire sensors.

Avoid service mishaps

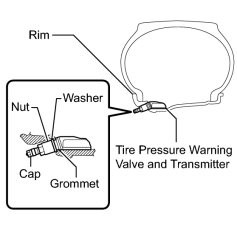

On direct TPMS systems, any service requiring the dismounting and mounting of tires can damage a sensor unit, including new tire installation and flat repairs. Other common service mishaps include inappropriate tool use, incorrect valve stem sensor installation and torque, and not replacing the nickel-plated valve core and rubber grommet in the valve stem.

Incorrect valve stem sensor installation and torque, and not replacing the nickel-plated valve core and rubber grommet in the valve stem can cause problems with the sensor. (Courtesy of Toyota.)

Another issue that seems to be a common concern is the weather, specifically in the climates of the northern US. The harsh winter weather affects the aluminum sensors causing them to oxidize on the inside.

Any service that requires the dismounting and mounting of tires can damage a sensor unit, including new tire installation. Proper tire machine technique is critical to not damage the sensor. (Courtesy of Toyota.)

Most indirect TPMS systems require resetting to recalibrate the system. A reset is typically required after adding air to a low tire, after changing or servicing a tire, or after rotating the tires on a vehicle. Finding the reset button and determining the reset procedure are the only difficult points to service.

With so many different reset procedures, it’s important to make sure you are using the right procedure for the vehicle being serviced. For example, since General Motors has more than 10 different procedures depending on the application, consult ChiltonLibrary for the proper procedure and the location of the reset button.

While TPMS systems offer increased safety to drivers through low pressure warnings, they are not meant to be a substitute for proper tire pressure maintenance. How frequently should you be checking tire air pressure? Certainly any time the ambient temperature changes dramatically, and follow the manufacturer’s maintenance intervals and specified inflation pressures.

You can access Chilton’s comprehensive service procedures, specifications, and wiring diagrams on our resource page.

By Jim Marotta; Originally posted on blog.gale.com